Pour vous offrir la meilleure expérience, nous utilisons des cookies pour faire fonctionner le site, mesurer l’audience et adapter le contenu. Vous pouvez tout accepter, refuser les cookies non essentiels ou personnaliser vos choix. En savoir plus dans notre politique de cookies.

Vous gardez le contrôle. Ajustez à tout moment ce que nous stockons sur votre appareil — vous pouvez rouvrir ce panneau depuis le pied de page. Pour plus de détails, consultez notre politique de cookies.

Vous trouverez ici vos commandes, avoirs, points de fidélité et bien plus encore !

Identifiez-vous

Vous trouverez ici vos commandes, avoirs, points de fidélité et bien plus encore !

Identifiez-vous

Livraisons et retours

Livraisons et retours

France / Europe

Retraits en magasin

Retraits en magasin

lundi - vendredi / 9h-12h / 14h-17h

Paiement 100% sécurisé

Paiement 100% sécurisé

4 fois sans frais

Service client

Service client

de qualité

Foire aux questions

Foire aux questions

Découvrez notre aide en ligne

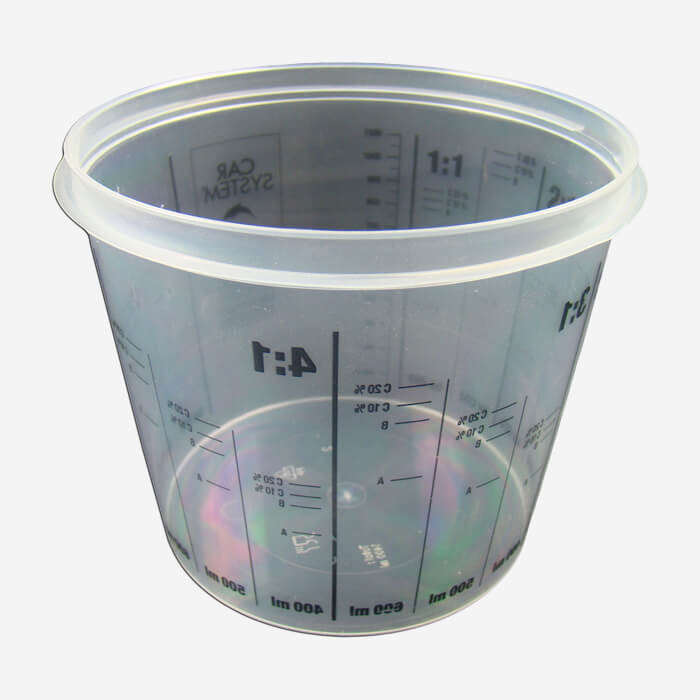

Table de conversion

Sicomin Surf Clear EVO epoxy system is:

- specially formulated for the manufacturing of surf boards.

- suitable for hand lay up of glass, carbon, aramid, natural and synthetic fibers.

- compatible with all commercial foams: polystyrene, polyurethane, cross-linked & linear PVC foams and others.

- compatible with all typical fillers used in the surf Industry.

Characteristics:

High mechanical performance epoxy system recommended for surfboard production.

Yields surfboards with a flexible touch, high temperature and UV stability.

High surface and' plug finishing, for high gloss requirement.

Other applications: surf repairs, fin boxes & plugs, pattern and model coating, etc...

Low odor and reduced skin aggression for a better work environment.

Hardeners:

3 hardeners EVO are available with the same mixing 2 / 1 ratio by volume.

- Medium hardener is designed for big boards or high ambient temperature applications (over 35 °C).

- Fast hardener is designed for classic boards In mild temperature working conditions (around 20"C).

- Super-Fast hardener is designed for fast lamination, gloss and repairs or low temperature application conditions.

Advices for application:

Work in a clean environment with heating facility.

Ideal working temperature from 18 °C to 30 °C.

Maintain a constant temperature during lamination.

Avoid high ambient humidity.

Avoid exposure to U.V. during the cure. Laminates and coatings benefitting from a sun free post cure or polymerized for at least 7 days at 18°C will obtain greater U.V. resistance and mechanical properties

Do not dilute with solvents. Please consult our technical assistance.

The use of compatible pigments is possible.

Keep packaging well-sealed as hardeners are sensitive to carbonic gas and humidity.

A polyurethane or other top coat paint can (for best UV protection) be applied, without primer, after sanding the final

layer of Surf Clear EVO.

*SICOMIN Is heavily involved in green chemistry. When technology and availability of raw materials allows, we choose

raw materials from biomass sourcing. Surf Clear EVO epoxy resin is manufactured with a green carbon content of 40 %.

*Hardeners react with carbon dioxide and moisture. Need to be kept in its original closed container. Avoid to a maximum any contact with air. If the aspect becomes cloudy, do not use.

Epoxy resin Surf Clear EVO

| Aspect | Liquid | |

| Color | Light purple | |

| Color Gardner | 2 maximum | |

| Viscosity (mPa.s) | @ 15°C | 5100 ± 1020 |

| @ 20°C | 2700 ± 540 | |

| @ 25°C | 1550 ± 310 | |

| @ 30°C | 950 ± 190 | |

| @ 40°C | 400 ± 80 | |

| Density | @ 20°C | 1.18 ± 0.01 |

| Refractive index | @ 25°C | 1.5452 |

| Storage stability | Ambiant | 2 years minimum. Cristalization free |

Hardeners EVO

| Ref | SD EVO Medium | SD EVO Fast | SD EVO Super Fast | |

| Aspect / Colour | Clear liquid | Clear liquid | Clear liquid | |

| Color Gardner | 1 max | 1 max | 1 max | |

| Viscosity (mPa.s) | @ 15°C | 215 ± 45 | 450 ± 90 | 650 ± 130 |

| @ 20°C | 145 ± 30 | 290 ± 60 | 400 ± 80 | |

| @ 25°C | 100 ± 20 | 190 ± 40 | 270 ± 54 | |

| @ 30°C | 70 ± 15 | 130 ± 25 | 180 ± 36 | |

| @ 40°C | 40 ± 10 | 68 ± 15 | 90 ± 18 | |

| Storage stability | 15 to 25°C | 24 months | ||

| Density | @ 20°C | 0.992 | 1.006 | 1.022 |

| Refractive index | @ 25°C | 1.5118 | 1.5181 | 1.5234 |

Fiche technique

Vous aimerez aussi

A propos

Futures Fins

Enjoy shape and shapers

SHAPERS COMPOSITES CO

Resin Research

© 2026 - Viral Surf

check_circle

check_circle