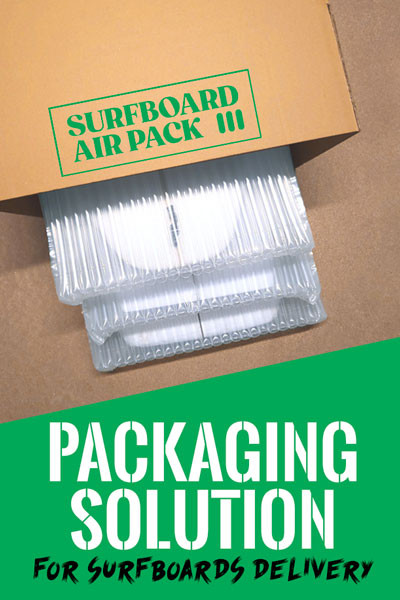

Transport

Make an inventory of the package and the goods with the carrier. Note all possible damage on the delivery slip and sign it. Thank you for taking the time to inform us of complaints and to check the consistency between the products delivered and the attached invoice as soon as possible. In the absence of a complaint on your part with the carrier and upon receipt of your order, no recourse will then be possible to obtain reimbursement or replacement of damaged products.

If you receive a damaged foam blank, we advise you to systematically refuse the package and ask the carrier to return it to us.

If you have chosen this option by mistake, we invite you to contact us by email to info@viral-surf.com in order to proceed, if you wish, to the payment of the shipping costs and the shipping of your order.

Customer account

Product availability

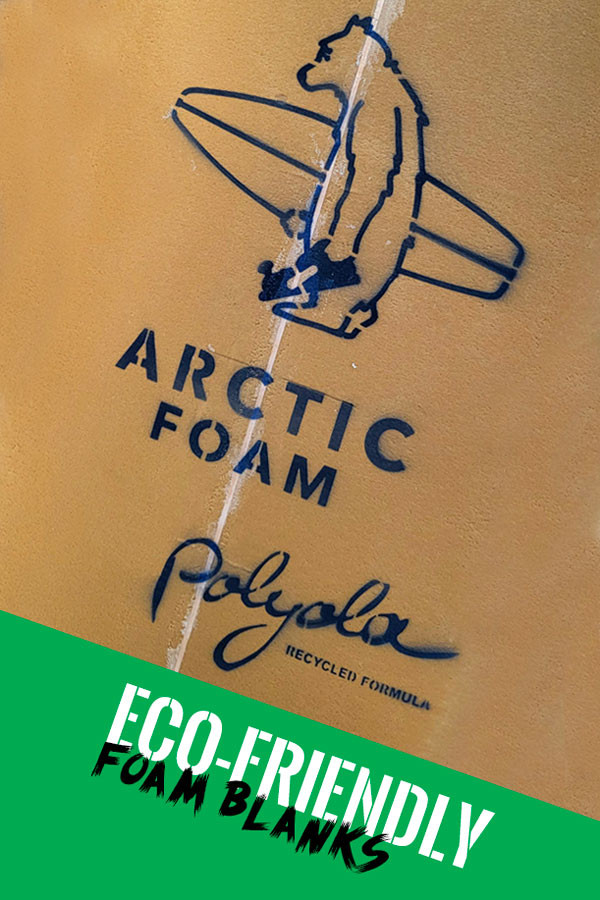

Foam blank

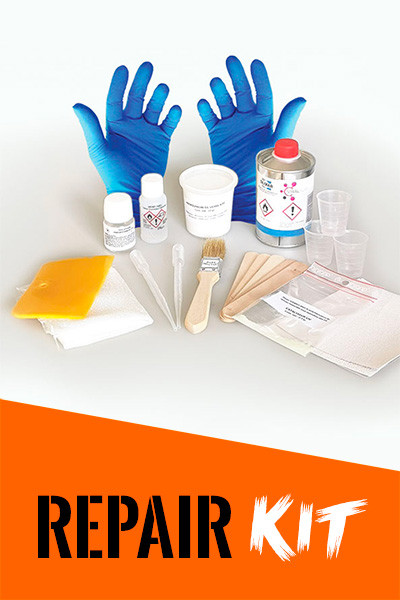

With a PU blank, you can use both silmar polyester resin and Sicomin epoxy resin.

With an EPS blank, on the other hand, only epoxy resin should be used. The polyester resin melts the polystyrene.

Note that for a beginner, it is preferable to work with polyester resin and PU blanks, the resin work and sanding being much easier.

The foam blank offered in the “CNC surf and pre-shape models category are the same blanks but having been machined in our workshop, by our KKL machine. The shaping work is well advanced here and the finishing of this stage much faster.

Under no circumstances will a foam blank, machined or not, be laminated without a minimum of "shaping" work

Shortboard <6 ": 50 €

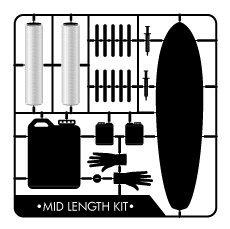

Mid lenght board <7''6: 55 €

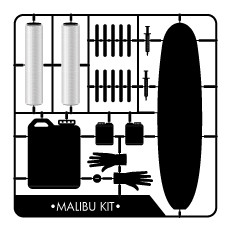

Longboard : 70 €

Lamination

Lamination of a polystyrene foam (EPS) blank = lamination only possible with epoxy resin. The polyester resin would melt your EPS foam blank!

Prefer the "classic" SIL249-A resin in the case of use with the addition of pigments (tinted resins), or in the case where you have chosen to work with a UV catalyst.

- the PMEK catalyst is generally preferred. It allows rapid polymerization of the polyester resin. Depending on the ambient temperature of your workshop - never below 16 degrees, and preferably below 30 ° - add 1 to 2% of catalyst for a gel setting of your resin in about 15 minutes. Warning: less than 1% and your resin could end up never drying fully and make sanding impossible; more than 2% and you may not have time to properly complete your lamination. Read the indications carefully!

- UV catalyst can replace PMEK. It allows the polyester resin to polymerize by exposing it to UV rays from the sun, or to UV lamps (recommended wavelength: 364nm). Infinite gel time as long as the resin is not exposed to sunlight; it is therefore an ideal alternative for "stress-free" layering. Be careful not to work in a room exposed to light, otherwise the resin will harden prematurely during your work.

The wax in styrene must be added up to 3% during the "hot-coat" step. It allows the sanding of the resin.

The monomer styrene allows it to thin the resin for "finish-coats" / "gloss", or when the resin is a little too thick.

Be careful, styrenes are dedicated to polyester resin; they must never be used with epoxy resin.

Polyester

| <6’’ | <7.6’’ | >8’’ | |

|---|---|---|---|

| Stratification | 700g | 1kg | 1.4kg |

| Hot coat | 350g | 500g | 600g |

Epoxy

| <6’’ | <7.6’’ | >8’’ | |

|---|---|---|---|

| Stratification | 650g | 850g | 1.25kg |

| Hot coat | 300g | 425g | 525g |

Warning: the dilution of the pigment with the resin must never exceed 3% of the total volume to allow polymerization.

English

English Français

Français Espagnol

Espagnol