Additives

Along the surfboard manufacturing process, you will certainly need some chemical additives : wax in styren, monomer styren, PMEK catalyst, UV catalyst, microbaloons, silica, aceton...

Filters (31 products)

There are 31 products.

VIRAL SOLAR RESIN ADDITIVE 10 GRAMS

Packaging | 10 gr

Polymerization | by exposure to UV

Additive for epoxy resins glassing / hot-coat - 1 liter

Brands | Sicomin

Packaging | 1 liter

Products | Epoxy additives

VIRAL SOLAR RESIN ADDITIVE 50 GRAMS

Packaging | 50 gr

Polymerization | by exposure to UV

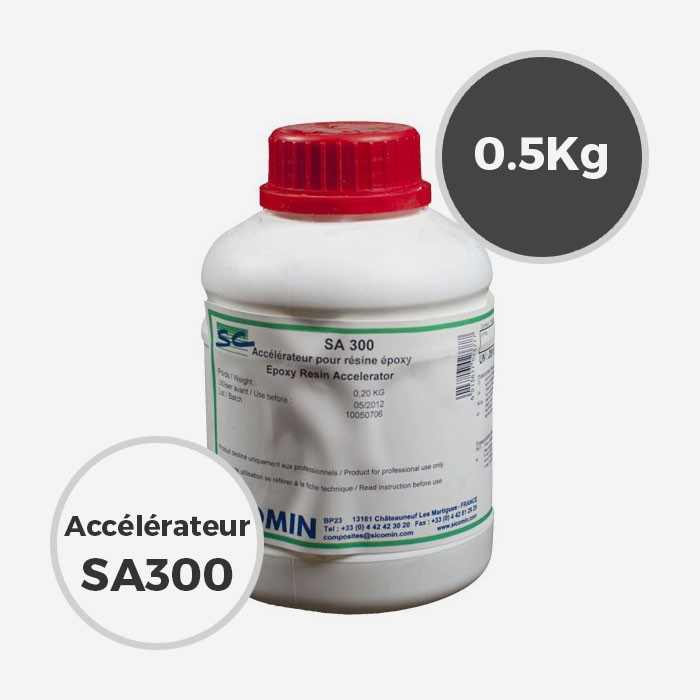

SA 300 Accelerator for epoxy resins - 0.5Kg

Brands | Sicomin

Packaging | 500 gr

Products | Epoxy additives

VIRAL SOLAR RESIN ADDITIVE 250 GRAMS

Packaging | 250 gr

Polymerization | by exposure to UV

English

English Français

Français Espagnol

Espagnol